When making vodka, a mash made from either rye, wheat, corn, potato, beet or molasses is used. Co-founded by Stafford Sheehan and Greg Constantine, a New York City-based company called Air Co. has instead created the world’s first carbon-negative vodka made from just CO2 and water.

In order to make the carbon-negative vodka, CO2 is first sourced from beverage manufacturing plants and ethanol factories. The CO2 is then liquefied at facilities powered by hydroelectric plants before being converted into ethanol at Air Co.’s facility.

Because the level of CO2 produced during the making of Air Co.’s vodka is less than the amount of CO2 captured, the vodka is regarded as being carbon-negative. To verify the carbon-negative status, Air Co. has conducted a life-cycle analysis (LCA).

“The capture, purification, compression and transportation emit around 0.1 kg of CO2 per 1 kg of CO2 that comes through our door, so our CO2 is 90 per cent carbon negative when it arrives before we do anything to it,” said Air Co..

“The carbon impact of the solar electricity we source to make the hydrogen adds roughly 0.1 kg of CO2 per kg that we convert,” added Air Co.. “The conversion process consumes about half the electricity of the hydrogen, we’re still 0.75 kg carbon negative after conversion. The boiler only adds another 0.08 kg of carbon emissions from the intensity of the solar electricity, bringing us to 0.67.”

The vodka is bottled by hand and is only available for purchase at Air Co.’s factory.

“Because Air Co distributes locally, the carbon dioxide emissions of its distribution are at most 0.07 kg per kg of carbon dioxide from our door,” explained Air Co..

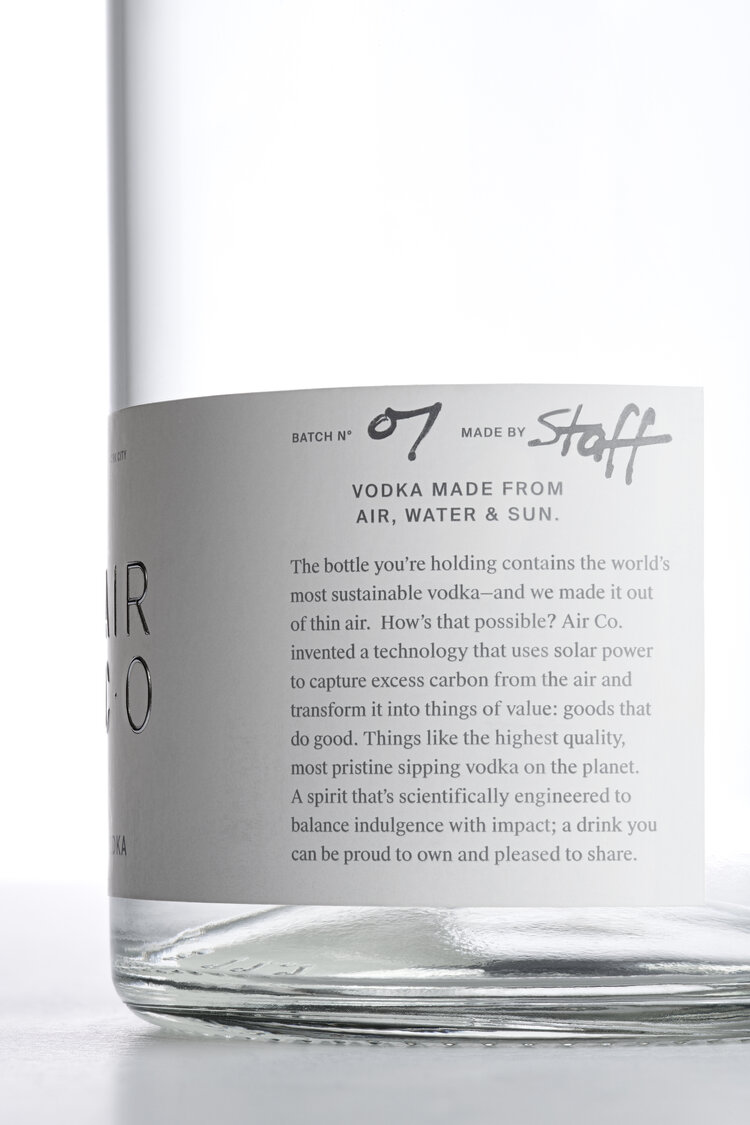

The packaging of Air Co.’s vodka is 100% recyclable and reusable. Designed by multidisciplinary practice Joe Doucet x Partners, the packaging features minimal labeling and uses a natural, non-toxic adhesive.